From Feasibility to Design & Delivery.

We know the drill.

Quick, accurate and reduced environmental impact

Our Approach

Each of the specialist drilling projects we undertake follows a proven, end-to-end process designed to ensure safety, precision, and reliability from planning through to reinstatement. And whilst we work to a pre-determined methodology our team of experts are well equipped to adapt and overcome any challenges that are unexpectedly presented along the way.

“ Every ground condition, route, and client objective is different , but the process of doing things properly never changes. Precision planning, technical skill, and a respect for the environment are what define successful drilling. ”

Every project begins with a detailed design and feasibility study. Our engineers assess ground conditions, route options, environmental constraints, and utility interfaces to determine the most effective solution. This early-stage planning ensures accurate design data, minimises risk, and sets a solid foundation for successful delivery.

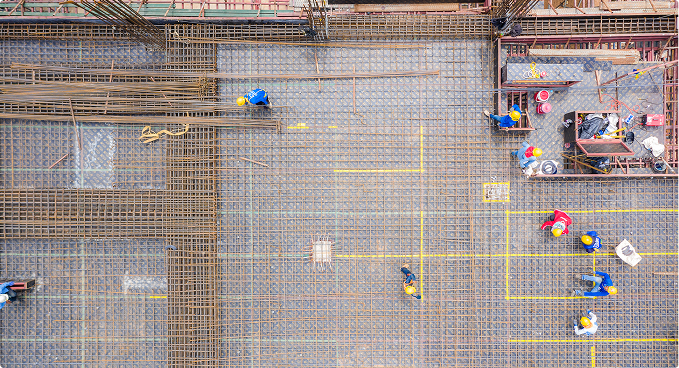

Before drilling begins, our teams complete all site establishment and preparation activities. This includes setting up drilling rigs, entry and exit pits, fluid management systems, and access routes, all in line with strict safety and environmental protocols.

Using advanced tracking and steering systems, our operators drill a precise pilot bore along the designed path. Continuous monitoring ensures the bore follows the correct alignment, depth, and gradient while safely navigating beneath existing infrastructure and natural features.

After completing the pilot bore, the hole is reamed and enlarged in a series of controlled passes to reach the required diameter for the product pipe. Drilling fluids are circulated to remove cuttings, stabilise the bore, and maintain optimal ground pressure throughout the process.

The prefabricated pipeline or duct is welded, tested, and positioned on rollers or supports ready for installation. It is then pulled carefully through the enlarged bore using the drill rig, ensuring smooth alignment, minimal stress, and complete structural integrity.

Before completion, every installation undergoes comprehensive inspection and testing to verify integrity, alignment, and performance. This may include pressure testing, weld inspection, and as-built surveys to confirm compliance with client and industry standards.

Once installation and testing are complete, Stockton reinstates all working areas to their original or agreed condition. Surfaces are restored, equipment is demobilised, and final documentation is issued to the client — delivering a fully certified and ready-for-service asset.

End-to-End Confidence

Each of the Horizontal Directional Drilling projects we undertake follow a proven, end-to-end process designed to ensure safety, precision, and reliability from planning through to reinstatement. And whilst we work to a pre-determined methodology our team of experts are well equipped to adapt and overcome any challenges that are unexpectedly presented along the way.