A DEPENDABLE FLEET

READY FOR SWIFT

DEPLOYMENT

AS FRONTLINE SPECIALISTS IN TRENCHLESS TECHNIQUES, CIVILS, AND PIPELINES, WE HAVE AN EXTENSIVE FLEET OF OWNED, WELL-MAINTAINED EQUIPMENT THAT ENSURES PROJECTS CAN MOBILISE WITHOUT WAITING FOR THIRD PARTIES.

OUR FLEET INCLUDES DEDICATED TRENCHLESS RIGS, GUIDANCE SYSTEMS, PUMPING UNITS AND SUPPORT PLANT, ALL MAINTAINED IN-HOUSE AND READY TO DEPLOY. THIS CAPABILITY IS MATCHED BY THE PEOPLE BEHIND IT. FROM EARLY PLANNING THROUGH INSTALLATION AND LIVE OPERATIONS, OUR TEAMS BRING CLARITY, EXPERIENCE AND PRACTICAL JUDGEMENT TO EVERY STAGE OF A PROJECT.

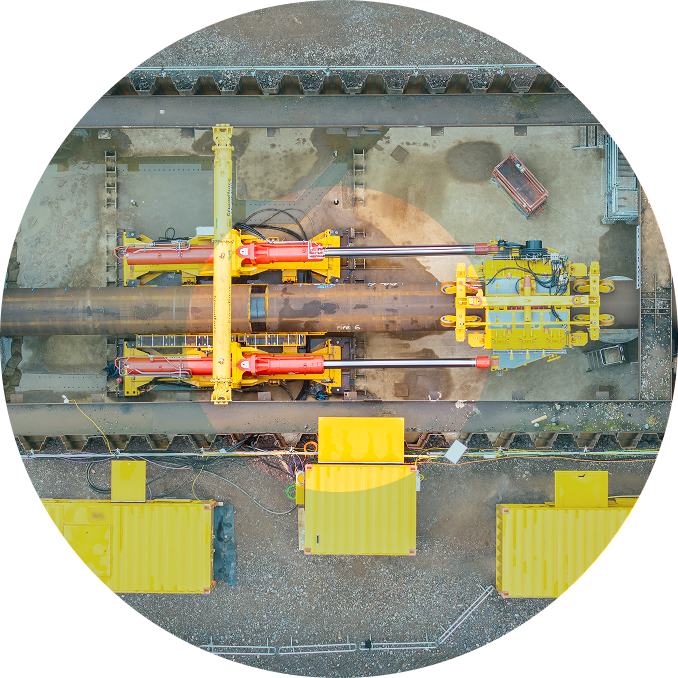

Direct Pipe®

Direct Pipe® technology offers a fast, precise, and low-impact method for installing pipelines beneath challenging terrain. Combining the advantages of micro-tunnelling and HDD, it enables simultaneous excavation and pipe installation in a single pass, delivering exceptional accuracy and efficiency, even in solid rock or complex ground conditions.

Our Direct Pipe® fleet includes microtunnel boring machines (MTBM) to excavate the soil, pipe thrusters to drive the machines forward and retract the pipeline or machines if needed, as well as separation plants and high-accuracy guidance systems designed to perform in difficult ground, including mixed geology and solid rock. High steering control and real-time monitoring deliver exceptional line and level accuracy, even on constrained sites.

With its reduced site footprint and high steering control, Direct Pipe® is ideally suited to projects near sensitive environments or critical infrastructure. Supported by our dedicated Direct Pipe® fleet and experienced specialist crews, Stockton delivers safe, efficient, and proven installations from start to finish.

Horizontal Directional

Drilling (HDD) Rigs

As a specialist HDD contractor, we deliver projects across numerous sectors including environmental and transport infrastructure. In particular, we specialise in using HDD techniques to install landfall/shore approaches for clients in the offshore renewables sector.

Horizontal Directional Drilling provides a safe installation system for pipes, ducts and cables where conventional open cut methods are not permitted, practical or viable. The process causes very little disruption to infrastructure and has minimum impact on the environment.

Our HDD capability includes mid-range and large-rig drilling units, high-pressure mud systems, recycling plants and downhole tooling configured for long, complex bores. These systems allow safe installation of pipes, ducts and cables where open cut methods are not viable or permitted.

We routinely deliver pipeline diameters from 6inch (150mm) to 48inch (1200mm), with bore lengths ranging from a few hundred metres up to two kilometres.

We have various sizes of HDD rigs available, with pulling forces ranging from 45 to 500 tonnes, and power packs with outputs ranging from 278 to over 1,000 kilowatts.

Each rig includes a rotating drill rod, guided by a surveying system behind a drill bit. During drilling, as part of the mud circulation system, mud pumps convey drilling fluid directly to the nozzles attached in the drill bit.

There are five basic configurations of rigs:

• Frame rig: With a low dead weight, a frame rig is easy to transport, with a standard crane sufficient for loading, unloading, and alignment on the drilling site.

• Trailer rig: Suitable for simple transportation as a semi-trailer, a trailer rig can be coupled and uncoupled quickly without additional auxiliary equipment, with no crane required for rig up and rig down. Its flexibility makes it ideal for projects with multiple boreholes.

• Crawler rig: Ideal for sites with rough terrain, crawler rigs have robust and easily manoeuvrable caterpillar tracks for full autonomous mobility in areas where trucks or cranes can’t access.

• Modular rig: Good for simple transportation to remote regions, modular rigs can be disassembled into two or three modules and transported in standard containers.

• Compact rig: Built for smaller projects and inner-city applications, the compact rig can be used flexibly in confined spaces.

For the pipe handling we use mobile screw units, mobile breakout units, and a rod crane. For mud handling we use high pressure pumps, mud pit pumps, feeding pumps, bentonite filters and separation technology.

Our downhole tools include the full-face opener which reams the pilot hole in a single pass, the downhole jet pump which effectively cleans the borehole, and a weeper sub to improve material flow.

Plant equipment

We also have an extensive fleet of plant and equipment including 750 ton direct pipe machines, 250t HDD rig, excavators, rollers, dumpers to support our drilling projects, as well as our Civils division.

Whatever the project, this range of equipment helps to efficiently manage groundworks and infrastructure requirements.